Evolution of Jimani’s Low Cost Hybrid Laser Marking Systems

The Low-Cost Hybrid Laser Marking Systems have become the mainstay of Jimani's laser marking system...

By: Jim Earman on 3/6/24 1:14 PM

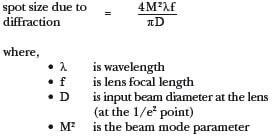

Let’s start by describing what a beam expander does. A fixed expansion ratio beam expander typically consist of 2 lenses that comprise a simple Galilean telescope. The purpose of a beam expander is to change the diameter and beam divergence characteristics of a laser beam passing through it. Beam expanders are usually used to enlarge the laser beam diameter prior to passing through the focusing lens of the marking system. The effect of enlarging the beam diameter into the focusing lens is to reduce the size of the focused laser spot at the work piece.

Note that focused spot size is inversely proportional to Beam Diameter D

Enlarging the beam to twice its original diameter will cause a two times reduction in the size of the focused laser spot at the work. If the size of the focused spot at the work can be reduced by a factor of two then the resulting power density at the work will increase by a factor of four since all of the power of the laser through the lens is now being concentrated into a spot that has ¼ the area of the focused spot without the beam expander. This can be a pretty big deal.

Conversely, if the beam expander was used as a beam reducer, the effect would be to reduce the size of the laser beam going into the lens and the focused spot size at the work would be enlarged. If the size of the beam going into the lens was reduced by half then the size of the focused spot would double and the resulting laser power density at the work would be reduced by a factor of four. You might ask, why would one want to reduce the laser power density at the work. There is actually a pretty good reason to do that at times.

The best and most common wavelength (color) of laser light for marking and engraving metal is 1064 nanometers. For decades, the only way to produce 1064 nm light at useful power levels was with a YAG laser. The quality of the light coming directly out of a YAG laser is very poor and, if the laser beam coming directly out of a YAG laser was directed into a focusing lens, the focused spot size was so large that there was not enough laser power density to have much affect on a metal work surface. One of the ways to improve the quality of the laser beam out of the laser was to pass it through a beam expander. Remember, the larger the beam into the lens, the smaller the focused spot at the work. YAG lasers typically used beam expanders in the 6X magnification range and, by enlarging the beam into the lens by 6X, the size of the focused spot could be reduced by a factor of 6 and the laser power density in the focused spot could be increased by 36. By doing this, the focused spot now had enough power density to burn into metal surfaces.

One might ask, “If increasing the size of the beam into the lens can also increase the power density at the work piece, why not increase it even more, say by 20X or 30X?” The main reason has to do with limitations on the size of the mirrors in the scanhead that move the laser beam back and forth over the work in order to mark the characters or draw the patterns that one is looking for. The expanded laser beam has to fit onto those mirrors and it becomes impractical to have extremely large mirrors in the scanhead for space and speed reasons. Larger mirrors have more size and mass and marking times increase exponentially as mirrors get larger. Scanhead mirrors of 10-15 mm in diameter are typically used in modern day scanheads.

About 8 or 10 years ago fiber lasers had improved to the point of having enough output power to perform the same tasks that had been previously limited to YAG lasers. Fiber lasers produce the same wavelength of light as YAG lasers and can be used effectively on the same materials, primarily metal. Fiber lasers also have a number of advantages over YAG lasers in terms of input power to output power efficiency, size, elimination of maintenance and consumables, reliability and life expectancy. Fiber lasers also put out a much higher quality laser beam directly out of the laser and, if that output beam is sent directly into the focusing lens, the focused spot has sufficient power density to do much of the same work done by a YAG laser with a beam expander. So, the beam expander could just be eliminated without any penalty, right? Not necessarily…..read on please.

The size of the output beam directly out of a fiber laser used in a laser marking system is almost always larger than the output beam directly out of a YAG laser. A typical YAG laser beam diameter would be around 1.2 to 2.0 mm in diameter, with nominal sizes around 1.5 mm. Even a 2.0 mm YAG output beam could be passed through a 6X telescope and the resulting 12 mm beam would still fit onto the mirrors of a scanhead with 14 mm mirrors. The result would be a 36X increase in power density at the work. Great!

A typical fiber laser used for marking applications will have an output beam size directly out of the laser of about 8 mm or so. Even though the higher beam quality from a fiber laser will allow it to focus to a relatively small spot without a beam expander, the size of the focused spot could be reduced further if that output beam was passed through a beam expander. The result of that smaller focused spot size would be an increase in laser power density at the work piece. Since the output beam from a fiber laser is larger and the size of the scanhead mirrors is limited, beam expanders with expansion rations of 6X or so will not work. But, if the size of the beam expander was reduced to, say 1.5 X, that 8 mm output beam from the fiber laser would only increase in size to 12 mm and would fit on a typical scanhead mirror. A beam expander of only 1.5X will still more than double the power density in the focused spot. That is also great, no matter how anyone might try to spin it.

If the beam expander was built so that it could be used facing either direction, it could also be used to decrease the size of the beam into the focusing lens and increase the size of the focused spot at the work resulting in a proportional decrease in power density. Why might one do that? Well, some materials just mark better with larger focused spot sizes and some processes, such as stain marking, demand larger focused spot sizes or they just don’t work as well. I won’t go into all of the details of that in this post but, if the reader is interested, more detailed information can be found here.

Beam expanders add cost to a marking system. Although a fiber laser marking system could eventually perform the same tasks with or without a beam expander, life gets easier and marking gets faster having one to use. Laser marking is not a “one focused spot size fits all” process but, like most things in life, workarounds can be found. My take on all of this is as follows:

When it became evident that fiber lasers would replace YAG lasers for metal marking applications, all of the integrators, including Jimani, jumped on the fiber laser bandwagon. Because fiber lasers were so much smaller than YAG lasers, most integrators became, in my opinion, overly enamored with size. The laser source no longer needed to be this big, heavy, long YAG laser and the fiber laser output device (called a collimator or isolator) could just be mounted directly onto the scanhead with no other optics in between. While it is true that this technique allowed the laser and beam delivery system to be very small and compact, it is also true that it limited the user to a single focused spot size unless the lens was placed out of focus on the work which is generally a terrible idea. I knew that our job shop business would be far better off if we had different focused spot sizes available to us and so we designed a reversible beam expander into our system. Although it added cost to our system, the performance and flexibility improvements have completely justified the expense.

None of the inexpensive imported systems, to my knowledge, use beam expanders. but, Jimani’s Low Cost Hybrid Fiber Laser Marking systems now include a reversible 1.5X beam expander on all fiber laser marking systems. It is also true that most laser marking applications can be performed without a beam expander even though the process might not be as efficient. As is the case with variable pulse width fiber lasers, only a few applications demand the use of a beam expander, life just gets easier having one.

The Low-Cost Hybrid Laser Marking Systems have become the mainstay of Jimani's laser marking system...

Industry: Medical

Material: Stainless steel

Mark Data Type: Logo + text

Laser Mark Type: The black...

Fiber lasers are an ideal tool for many stainless steel marking applications. The fiber laser...