Types of Laser Marking

Types of laser marking generally fall into one of three categories: Ablation, Engraving and Stain...

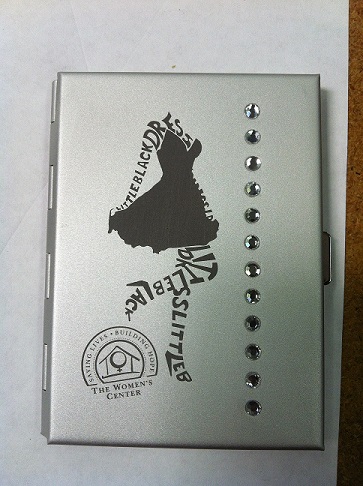

Laser marking by ablation requires removing a film or layer of material on the part. The bright white laser marking achieved on anodized aluminum is an example of laser ablation marking. The anodize is removed or ablated away and a white oxide layer formed on the surface of the part yielding in a white mark.

Engraving or etching is exactly as the name implies. The focused laser beam will remove material from the surface of the part by vaporizing it. This results in marking depths as deep as .1 inches. Deep laser engraving almost always requires multiple laser passes with each pass removing a thin layer of material.

Stain marking is one of the most useful marking techniques for fiber lasers, but it is also one of the most misunderstood techniques. Stain marking can provide a permanent, dark mark on stainless steel, titanium and hard chrome. The laser stain mark is accomplished by using a relatively large focused spot size in order to heat the surface of the part sufficiently such that an oxide layer is formed on its surface. The heat from the laser beam is not however sufficient enough to vaporize material from the surface.

Laser part marking delivers extremely reliable, consistent, and long lasting permanent marking to just about any material. The Langolier fiber laser marking system is designed to be easy to use, rugged enough for harsh manufacturing environments, and flexible so that your always make your best mark.

Please contact us if you are interested in laser marking systems.

Types of laser marking generally fall into one of three categories: Ablation, Engraving and Stain...

Fiber lasers are an ideal tool for many stainless steel marking applications. The fiber laser...

Let me qualify this post by first stating that I am not a metallurgist so please don't pick me...