Laser Engraving Brass Nameplates

Industry: Nameplate

There are three or four good laser marking software packages on the market. They are all pretty versatile and complete. Each one has a few unique useful features but, when all is said and done, they all let you mark parts with your laser. After all, there are only so many ways to move a laser beam around and turn on the laser. So just what makes one laser marking software package different and better than the others? The answer is a simple one...Support...Support with a capital "S".

I don't know every detail about every laser marking software  package but I do know enough to say with confidence that they all work. Laser marking systems sales is a competitive business with a sophisticated customer base. Laser marker owners and prospective buyers are always comparing software features and it becomes pretty easy to know which features are available in which package.

package but I do know enough to say with confidence that they all work. Laser marking systems sales is a competitive business with a sophisticated customer base. Laser marker owners and prospective buyers are always comparing software features and it becomes pretty easy to know which features are available in which package.

As I said, they all have similar capabilities. None of them are perfect. An end user will always find a way to use the marking software in a way that it has never been used before or tested with and sometimes software bugs or shortcomings are exposed. What differentiates one marking software package from another is how those issues are handled and whether or not the software company is receptive to fixes or changes that "just make sense".

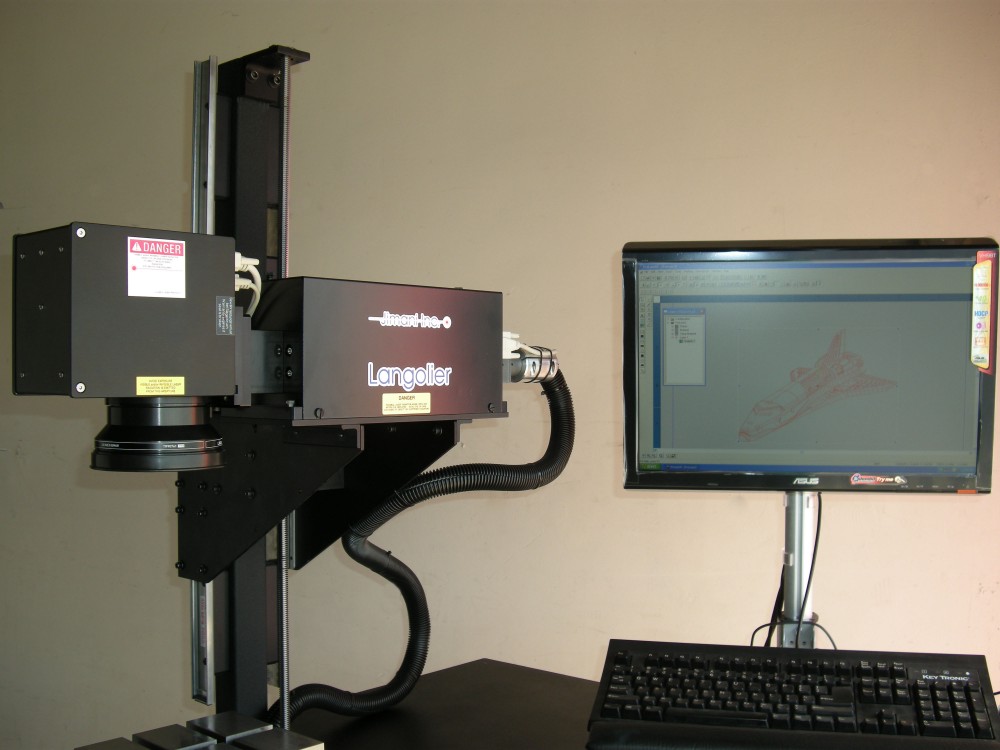

No one in the marking software business is as responsive as the authors of Prolase, American Laserware. Laser marking software is their only product and they know that they have to be responsive. I could give many examples of that responsiveness but I'll limit my comments to one: Several years ago, when fiber lasers were just being introduced into laser marking, I was supporting an installation of a new Langolier fiber laser marker in Wisconsin.

Early models of IPG fiber lasers, the fiber laser used in Jimani Langoliers, had a relatively long turn off time. The laser took about 250 microseconds to bleed the power down to 0 when it was commanded to turn off (current models of these lasers now have a 2 microsecond turnoff time). The long bleed off time caused "ghost" traces of laser marks on sensitive materials when the laser beam finished marking one vector line and jumped to the next vector line.

Langoliers, had a relatively long turn off time. The laser took about 250 microseconds to bleed the power down to 0 when it was commanded to turn off (current models of these lasers now have a 2 microsecond turnoff time). The long bleed off time caused "ghost" traces of laser marks on sensitive materials when the laser beam finished marking one vector line and jumped to the next vector line.

My customer in Wisconsin had some very sensitive materials that exhibited symptoms of "ghost" traces and the marking was unacceptable. A possible solution was to delay the jump from one vector to the next one in order to allow time for the power to bleed off. This solution had to be implemented in the marking software, Prolase XP. I phoned Keith Cudebec, the founder of American Laserware, at about 10:00am one morning, explained the problem, and by 4:00pm on the same day, a new release of Prolase XP was posted on their website for download. I was amazed, as was my customer.

I could mention many examples of extraordinary support from Keith and Pat Summers, President of America Laserware. I really don't care if other software packages work as well as Prolase. I really do care about the support that I receive when things aren't as they need to be and that is why Jimani integrates all of our lasers we sell and the ones we use in our laser job shop with Prolase.

Industry: Nameplate

This photo is a cast acrylic sign that we made for use at Jimani about 10 years ago. It is on the...

Industry: Automotive