What Is Laser Marking?

Generally speaking, laser marking is performed using one of two laser types and one of two types of...

By: Jim Earman on 1/17/12 3:39 PM

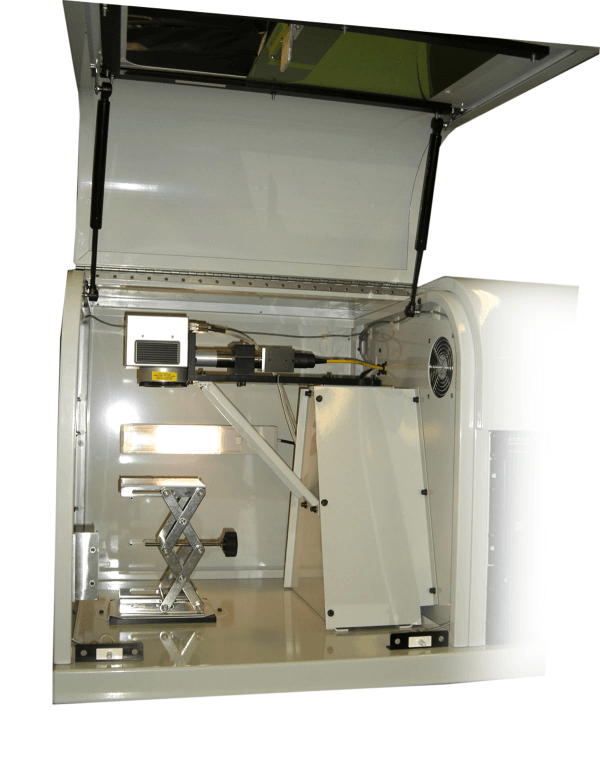

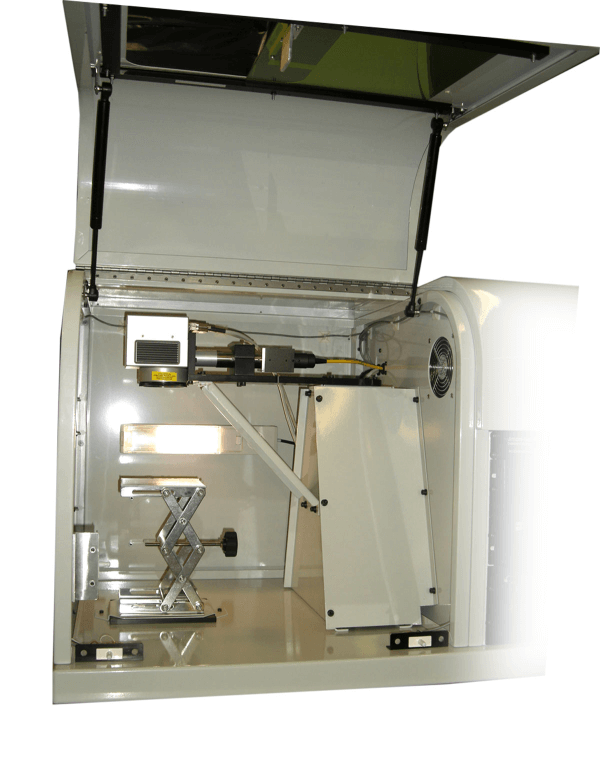

Generally speaking, there are two flavors of laser marking systems: Steered Beam and Flying Optics. Steered beam systems have a stationary focusing lens and mirrors above the lens move the laser beam in the X and Y axes to mark images in a plane at the focal distance of the lens.

Flying optics systems have the focusing lens attached to some type of X-Y translation system and the lens moves back and forth over the work piece to mark images. Marked images in both types of systems can be text, graphics or anything else that one might want to mark on a part.

have the focusing lens attached to some type of X-Y translation system and the lens moves back and forth over the work piece to mark images. Marked images in both types of systems can be text, graphics or anything else that one might want to mark on a part.

Steered beam systems generally act like plotters and flying optics systems generally act like dot matrix printers. Both types of systems have their place in the laser marking marketplace. This discussion is limited to problems and solutions associated with marking graphical images with steered beam laser markers.

Adobe Illustrator seems to be the graphics program of choice for many graphic artists today. It is a powerful program but usually does not provide the type of "ready to mark" graphics file demanded by steered beam laser marker to properly engrave graphics and logos. Illustrator files are not readily accepted by all versions of laser marking software. Additionally, Illustrator files frequently contain layers of multiple images and embedded objects that are not necessary or understood by laser marking systems. The same can be said of many other graphics creation packages, Autocad for example. Autocad files frequently contain un-necessary information and although the resulting file might look great when it's printed on a piece of paper, it contains more that the simple point to point line information that plotters require. Remember, I said that steered beam laser marking systems act like plotters, not printers.

Years ago (long before Illustrator became a graphics artist standard), most laser marking graphics arrived in the form of logos on business cards or printed business letterhead. To create a laser markable logo, the image was scanned and then either digitized electronically with a digitizing pad or "vectorized" using the limited vector tracing programs available at the time. For several years Casmate was the vectorization program of choice. Over time, Casmate disappeared and its replacement product was much more difficult to use and provided questionable results when engraving logos. The last Casmate products would not run in newer Windows environments or computers. Further to that, logos began arriving in electronic format and the need to scan and vectorize went away. But there was still a need to output the logo in a format that was clean and that the laser markers could understand and use. So just what does a laser marker need for engraving graphics and engraving logos? That requirement has not changed for years.

Repeating myself, I'll say again that steered beam laser markers work like plotters, not printers. In order to mark an image, the marking system needs to point to a location in the marking field, turn on the laser beam and then move to some other location as the laser beam draws a line on the work surface. The system must then turn off the laser beam, point to a new location, turn on the laser beam and then draw another line. This process continues until the image has been completely drawn by the laser marker. Marking an image with a steered beam laser marker is nothing more than a series of "move and draw" commands and any additional information in a laser marking graphics file is at the least, un-necessary and quite possibly not able to be understood by the laser marker.

The simplest form of a plotter file is a PLT file: the HPGL (Hewlett Packard Graphics language File) of years ago. For most applications, plt files have been replaced by more complex files that are intended to do more than just "move and draw". But nothing is more efficient or bulletproof than a simple plt file for laser marking graphical images with a steered beam laser marker. Everything in a plt file is reduced to "move and draw' commands. Nothing can go wrong. So the first requirement of a good laser marking graphics package is that it must be able to output a plt file.

Creating graphics to be marked larger than, say .5 inches high, is pretty easy. Small, good looking logos are much more of a challenge because laser line width becomes a consideration. A line drawn by the laser beam has some thickness. Imagine drawing a logo with a pencil. The thicker the pencil point, the less detail you are able to draw. The limiting factor to how much detail can be picked up in a laser marked logo is the line width, or thickness of the laser beam on the part. But all small laser marked logos can be improved by "thinning out" the logo in the graphics program. Imagine a very small letter O being drawn by the laser. As the laser draws the "hole" in the O, it will lend to close in because of laser line thickness. If the hole in the O could be made larger in the graphics program, it would look abnormal on the computer screen but would look completely appropriate when it was marked because the laser would thicken it back up. The more detailed the logo, the more important thinning it out becomes. So the ability to "thin out" a logo should be another requirement for a laser marking graphics package. It goes without saying that the graphics package should also have all of the easy to use tools that let a user add text, smooth out images and add lines where necessary.

When it became apparent that Casmate would not support Jimani's graphic needs in the future, we went on a search for another graphics program that would fill our needs. We chose Engravelab from CadLink. Originally we used Engravelab Version 5 but have since upgraded to Version 8. There are other graphics packages that do similar things but we've stayed with Engravelab because it works and is well supported. We've also become so good at using it that it allows us to support our customers who either have a requirement for quality logos or need our assistance learning how to use Engravelab efficiently.

We have provided a short video that takes one through the steps of creating a quality laser markable logo. Take a look if you are interested and feel free to contact us with comments or if you need help or assistance with logos for use with steered beam laser marking systems.

Generally speaking, laser marking is performed using one of two laser types and one of two types of...

Industry: Consumer

Editor’s Note: This article was first published in Photonics Online. You can read the original...